Product Description:

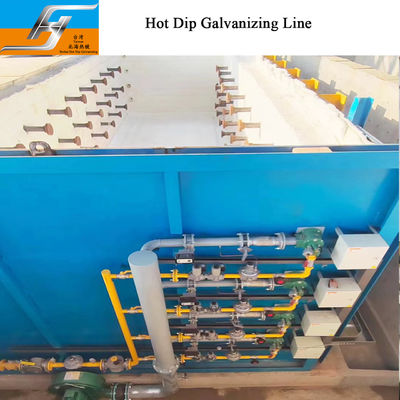

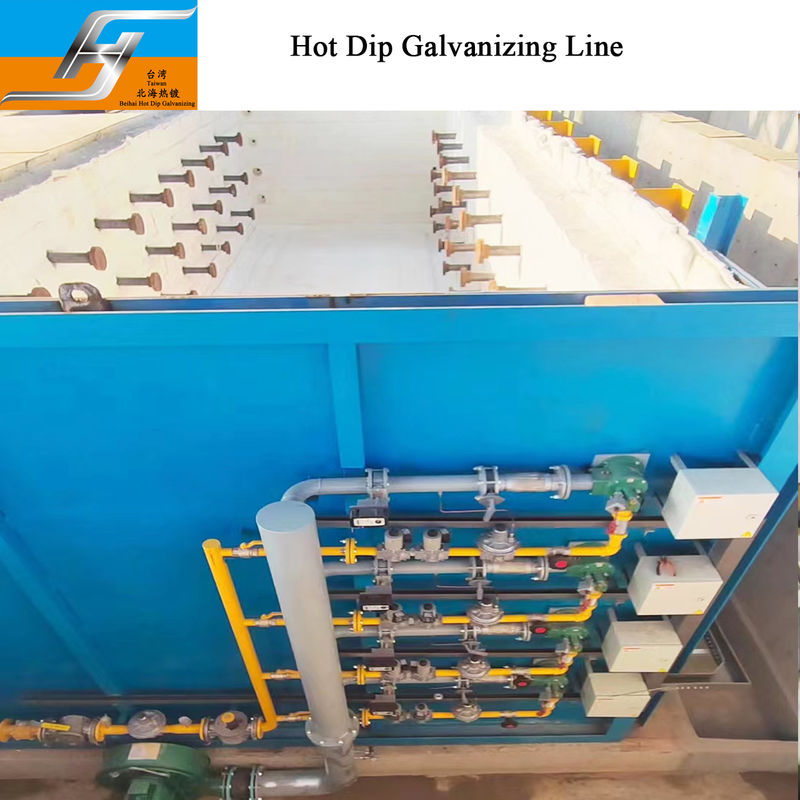

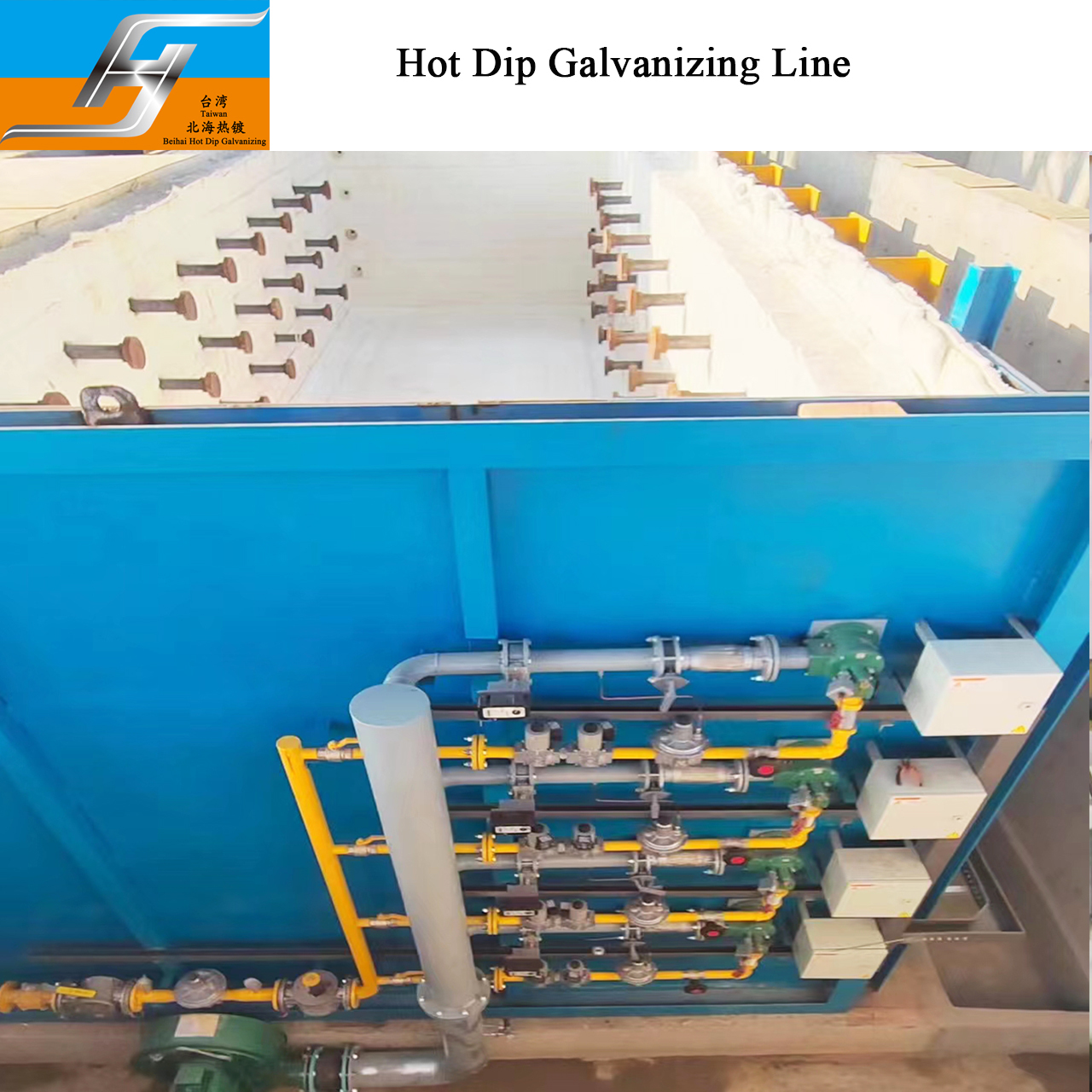

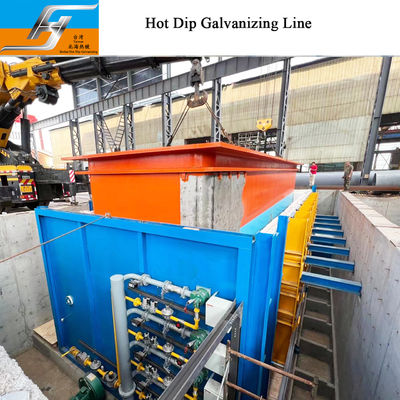

Our high-performance hot-dip galvanizing furnace typically exhibits the following key characteristics:

- Advanced Heating System & Temperature Control

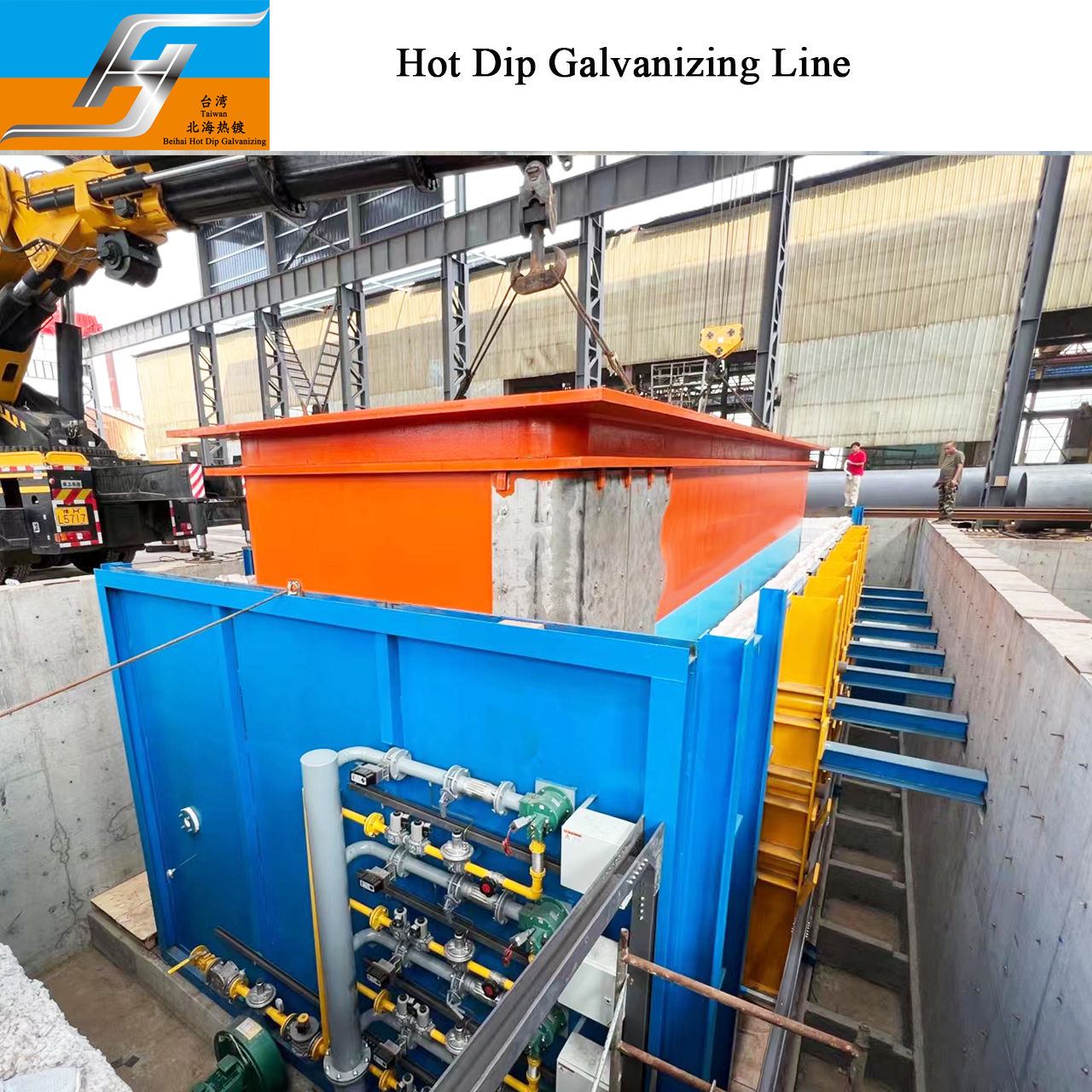

Utilizes high-speed burners (flame speeds up to 150 m/s) arranged strategically (e.g., diagonally) to ensure uniform heat distribution around the zinc pot, enhancing thermal efficiency. Precise PLC-controlled temperature regulation maintains zinc bath temperature within tight tolerances (e.g., ±5°C), critical for consistent coating quality and zinc kettle longevity.

- Energy Efficiency & Heat Recovery

Incorporates multi-stage waste heat recovery systems (e.g., U-shaped flues with heat exchange tubes) to preheat combustion air or auxiliary processes like pre-flux tanks, reducing energy consumption by up to 32%. Efficient insulation materials (e.g., phenolic boards) minimize thermal losses to ≤8.5 kW/m², aligning with stringent energy efficiency standards (e.g., Grade I ≤13m³ gas/ton steel pipe).

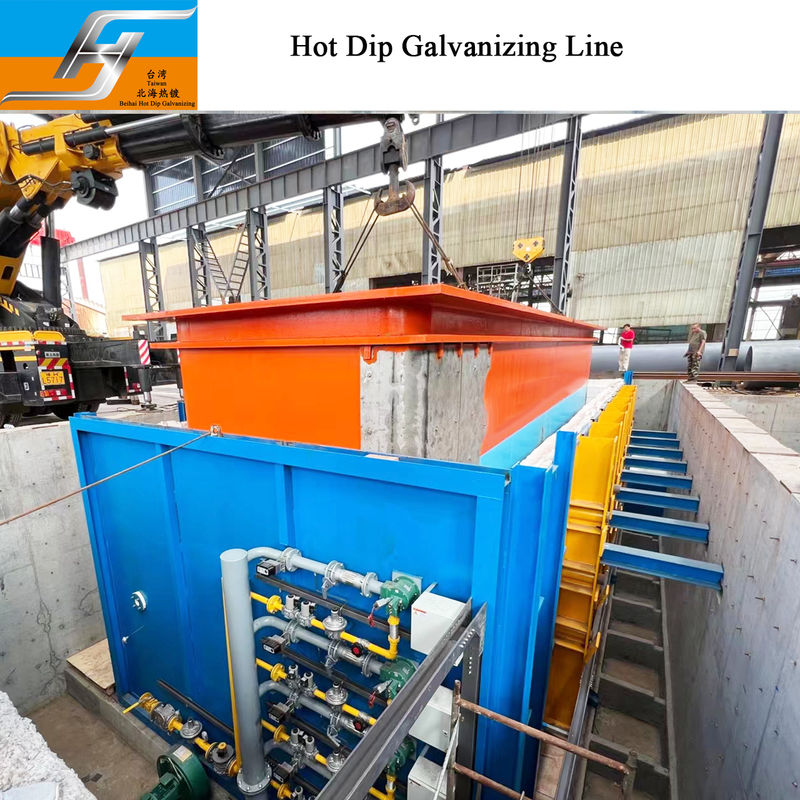

- Robust Structural Design & Zinc Kettle Protection

Features reinforced steel structures with low maintenance requirements and precise dimensions. Zinc kettles employ intelligent support systems (e.g., multi-point side bracing) to prevent deformation during prolonged heating. Integrated monitoring ports allow real-time corrosion inspection and thickness measurement.

- Enhanced Operational Safety & Automation

Equipped with comprehensive safety measures including dual shut-off valves, gas leak detection alarms, pressure safeguards, and automated ignition/flame monitoring systems. Crucible leak detection alarms provide immediate alerts for molten zinc breaches.

- Optimized Environmental Performance

Implements low-emission combustion technologies (e.g., multi-stage air preheating) to suppress nitrogen oxides (NOx ≤85mg/Nm³) and integrates exhaust treatment systems (e.g., dual-layer activated carbon filtration) to reduce particulate emissions (≤20mg/m³).

- Adaptability & Ease of Maintenance

Designed for flexibility across diverse fuel types (natural gas, LNG, electricity, diesel) and adaptable to various workpiece dimensions. Facilitates quick residue removal (e.g., via crane-chain systems for zinc dross clearance within 30 minutes) and features modular components for straightforward servicing.

Applications:

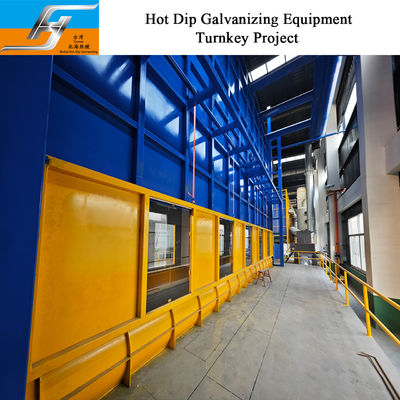

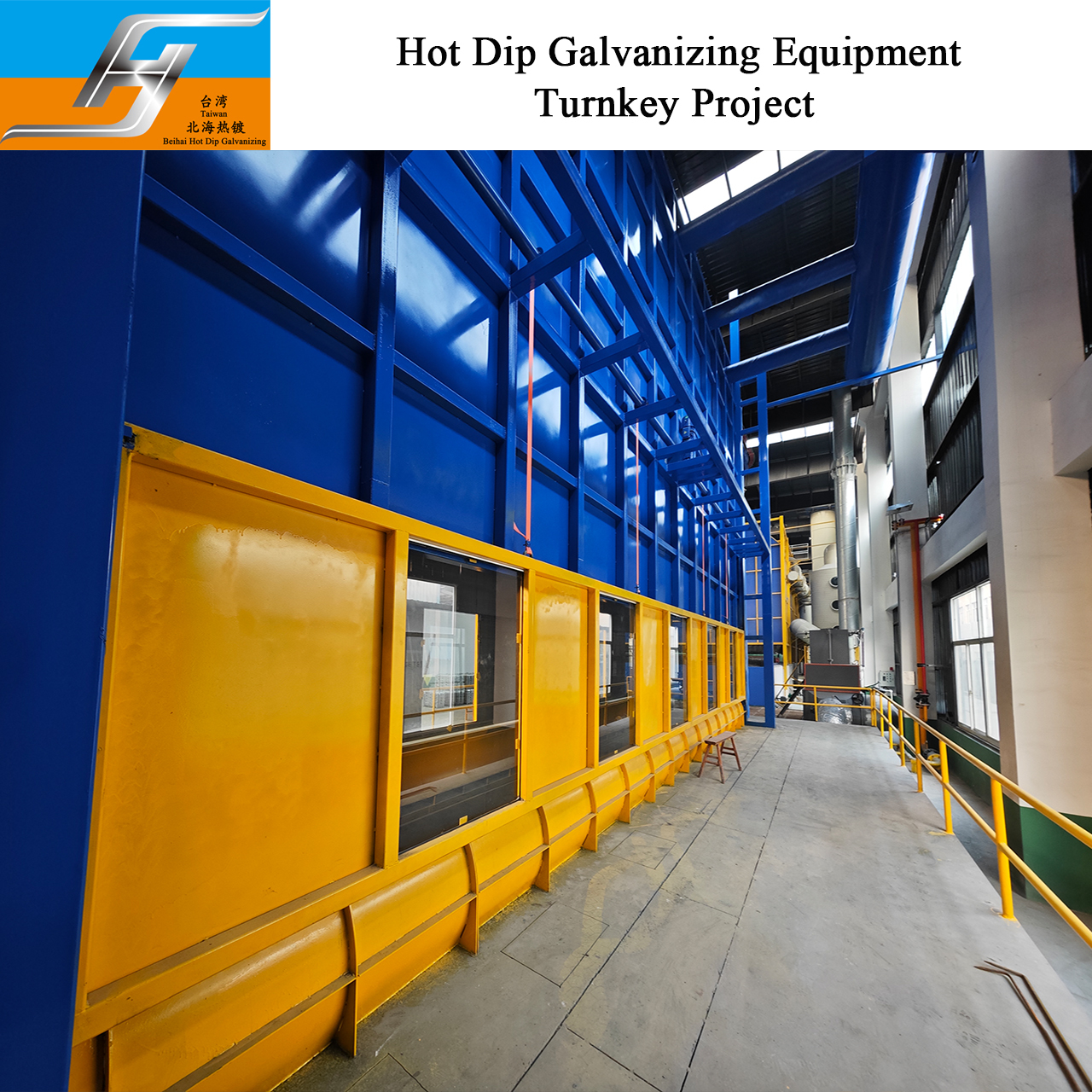

- BEIHAI GALVANIZING presents the Hot Dip Galvanizing Furnace, a top-of-the-line equipment designed for industrial applications. Originating from China, this furnace is tailored to cater to the specific needs of hot dip galvanizing factories around the world.

- The furnace boasts a customized design, ensuring that it can efficiently handle tools and standard parts with precision. Its high-velocity pulse-fired burner guarantees optimal heat distribution and energy efficiency, resulting in superior galvanizing outcomes.

- One of the key advantages of the BEIHAI GALVANIZING furnace is its ability to provide customized services to meet the unique requirements of different clients. This flexibility makes it a highly sought-after solution in the worldwide market for hot dip galvanizing equipment.

- Whether you are operating a large-scale galvanizing factory or a smaller workshop, the furnace can be tailored to suit your specific production needs. Its robust construction and reliable performance make it a dependable choice for achieving consistent and high-quality galvanized coatings.

Investing in the BEIHAI GALVANIZING Hot Dip Galvanizing Furnace means gaining access to cutting-edge technology and expert engineering that can enhance the efficiency and productivity of your galvanizing operations. Join the many satisfied customers around the world who have benefited from this top-of-the-line equipment for their galvanizing needs.

Support and Services:

Our Product Technical Support and Services for the Hot Dip Galvanizing Furnace include:

- Installation and commissioning guidance

- Training for operators and maintenance staff

- Troubleshooting assistance

- Regular maintenance and servicing options

- Upgrades and retrofitting solutions

- Remote monitoring and diagnostics capabilities

Packing and Shipping:

Product Packaging:

The Hot Dip Galvanizing Furnace is carefully packaged to ensure its safe delivery. It is protected with a combination of foam padding and sturdy cardboard boxes to prevent any damage during transit. The components are securely placed in the packaging to avoid shifting or breakage.

Shipping:

Our shipping process is efficient and reliable. The Hot Dip Galvanizing Furnace will be shipped using a reputable carrier service to ensure timely delivery. We take great care in handling the shipment to guarantee that the product reaches you in perfect condition. You will receive a tracking number to monitor the status of your delivery.

FAQ:

Q: What is the brand name of the Hot Dip Galvanizing Furnace?

A: The brand name is BEIHAI GALVANIZING.

Q: What is the model number of the Hot Dip Galvanizing Furnace?

A: The model number is BH001.

Q: Where is the Hot Dip Galvanizing Furnace manufactured?

A: The Hot Dip Galvanizing Furnace is manufactured in CHINA.

Q: What is the maximum temperature the Hot Dip Galvanizing Furnace can reach?

A: The Hot Dip Galvanizing Furnace can reach a maximum temperature of [provide specific temperature if available].

Q: Is the Hot Dip Galvanizing Furnace suitable for industrial use?

A: Yes, the Hot Dip Galvanizing Furnace is designed for industrial applications and is suitable for use in various industries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!