Product Description:

1. Superior Corrosion Resistance

Low Si/C content : Chemical composition strictly controlled (C<0.08%, Si≤0.03%) minimizes zinc liquid corrosion, extending service life by 3-5x compared to standard carbon steel.

Reduced Fe-Zn alloy formation : Slows intermetallic compound layer growth (e.g., FeZn₇/Fe₂Al₅) at 450°C operating temperatures.

2. Operational Efficiency

Slag reduction : Low Mn/P/S content (P≤0.035%, S≤0.035%) decreases zinc dross generation by 10-15% , lowering zinc consumption.

Thermal stability : Maintains structural integrity at 440-465°C continuous operation.

3. Manufacturing Adaptability

Weldability : Compatible with manual/automatic welding (GB/T 11345-89 BⅠ standard).

Formability : Supports hydraulic bending (R300mm curvature) without cracking.

Applications:

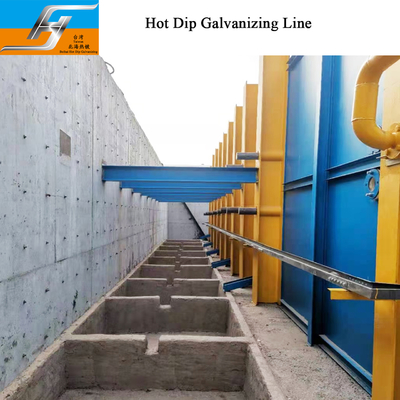

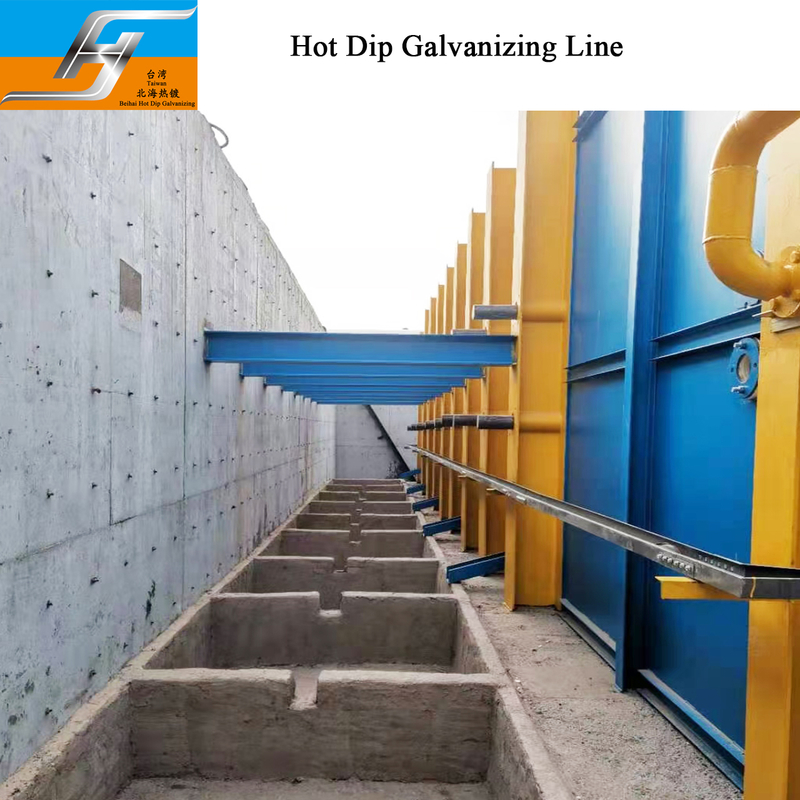

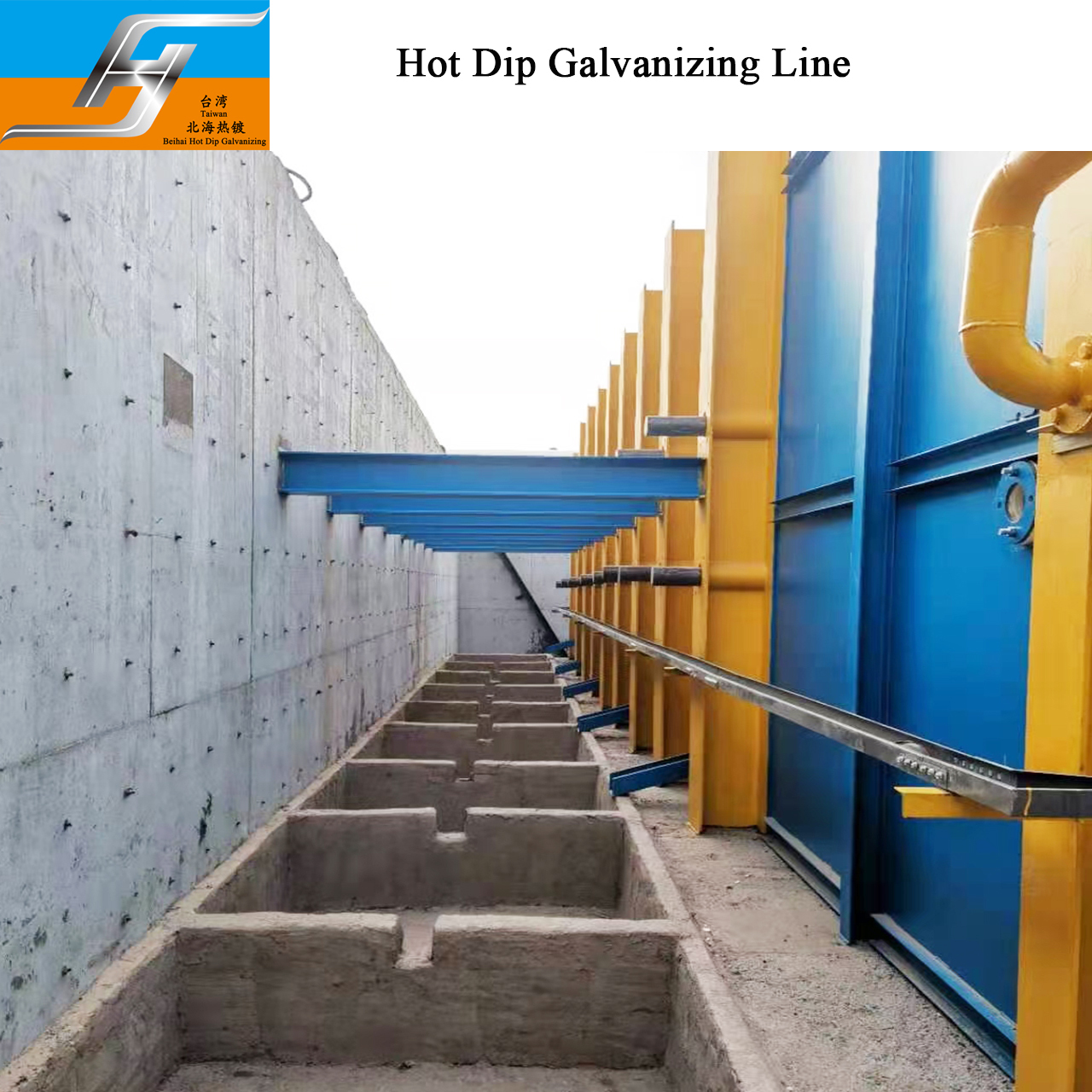

The Zinc Kettle product is a crucial component of a galvanizing furnace kettle, commonly known as a zinc bath, used in the hot-dip galvanizing process. This specialized equipment is designed to hold molten zinc at specific temperatures for the coating of steel substrates, such as Steel XG08, to provide corrosion protection.

- Product Application Occasions:

The Zinc Kettle is typically used in industrial settings where steel components need to be galvanized for outdoor applications. It is commonly employed in steel fabrication plants, automotive manufacturing facilities, construction sites, and infrastructure development projects.

- Product Application Scenarios:

1. Steel Fabrication Plants: The Zinc Kettle is utilized to coat steel beams, pipes, and other structural elements with a layer of molten zinc to prevent rust and corrosion in outdoor environments.

2. Automotive Manufacturing Facilities: The zinc bath is employed to galvanize car body parts, chassis components, and other steel parts to enhance their durability and longevity.

3. Construction Sites: Steel structures used in building construction, bridges, and utilities are often dipped into the Zinc Kettle to ensure long-lasting protection against the elements.

4. Infrastructure Development Projects: The galvanizing furnace kettle is indispensable for galvanizing street lights, guardrails, transmission towers, and other infrastructure components for increased lifespan and minimal maintenance requirements.

- Voltage: The Zinc Kettle is adaptable to customers' local voltage requirements for seamless integration into different industrial setups.

- Substrate: Designed to work with Steel XG08 and other steel grades commonly used in the galvanizing industry.

- Shape: Featuring a Round Bottom Round Corner design for efficient heat distribution and easy maintenance.

- Burner: Equipped with a High Velocity Pulse Fired Burner for precise temperature control and energy efficiency during the galvanizing process.

- Thickness: Available in 50mm or 60mm options to meet specific insulation and durability needs in various operating conditions.

Support and Services:

The Zinc Kettle product offers comprehensive technical support and services to ensure optimal performance and customer satisfaction. Our team of experts is available to assist with product installation, troubleshooting, and maintenance. Additionally, we provide training programs and resources to help our customers maximize the benefits of using Zinc Kettle. Whether you have questions about product features, operation, or compatibility, our technical support team is ready to help.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!