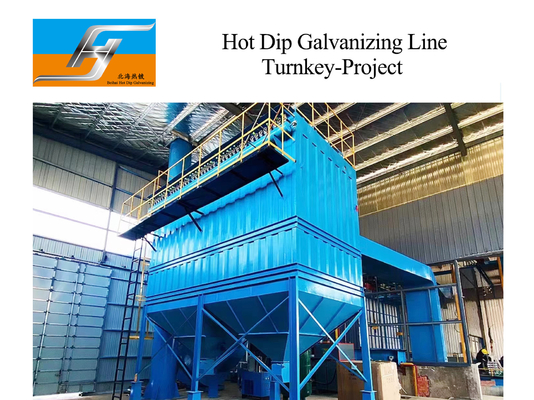

Product Description

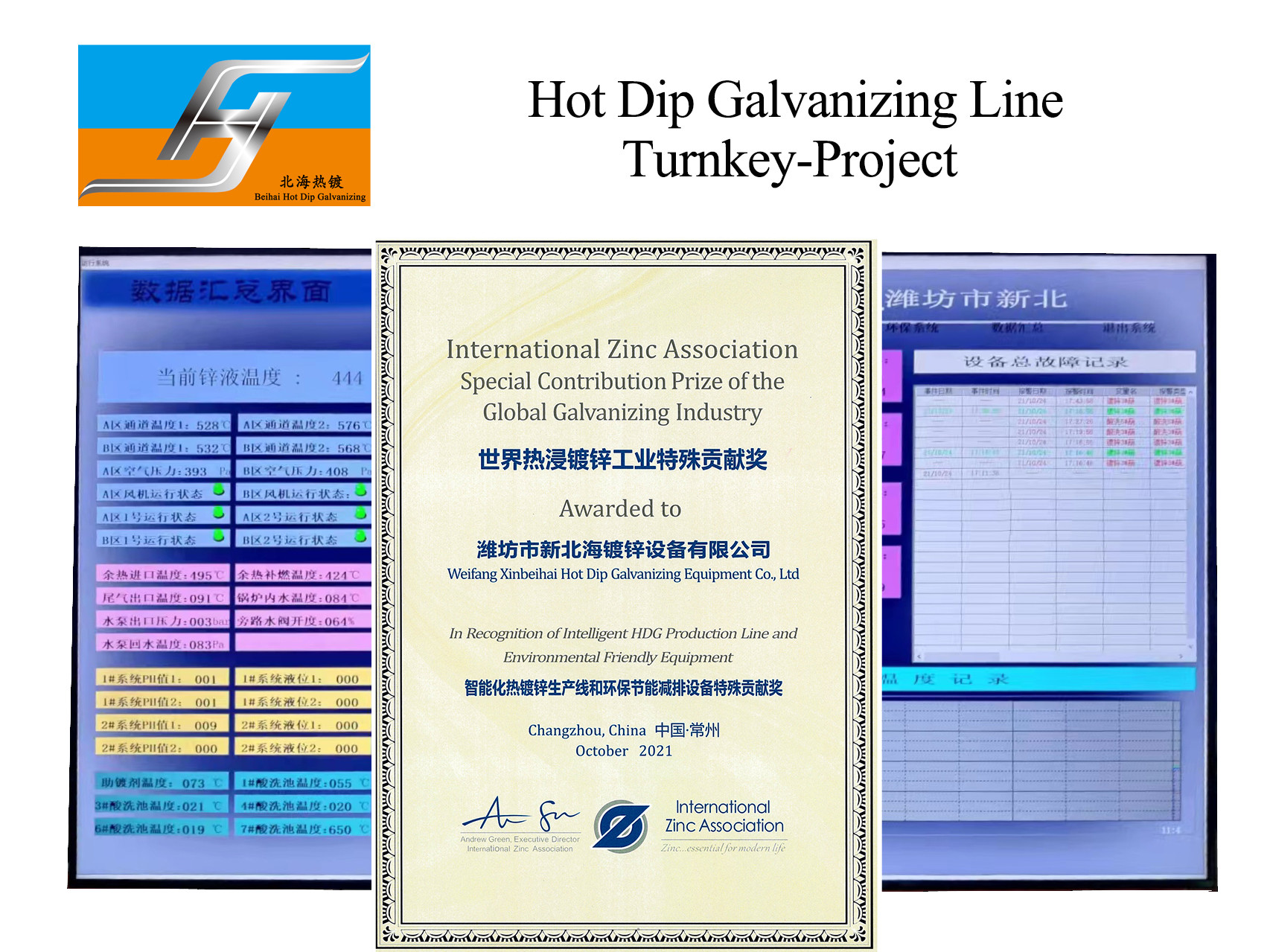

Industrial Hot Dip Galvanizing Equipment Production Line Turnkey Project One-Stop Service Supplier Manufacture Provide

Business Scope

- At present, we have the comprehensive capacity of the following: the design, manufacture, installation, commissioning and training of the hot-dip galvanizing lines and the improvement of old galvanizing plants.

- We can also offer galvanizing technology support besides equipment.

Main Equipment

- Hot Dip Galvanizing Line One-stop Service

- Hot Dip Galvanizing Technology Service

- Galvanizing Plant Design

- Furnace

- Zinc Kettle

- Galvanizing Specialized Monorail Crane

- Pickling Specialized Monorail Crane

- Acid Mist Treatment System

- White Fume Treatment System

- Wastewater Treatment System

- Waste Heat Heating System

- Flux Solution Iron Removal System

- Explosion-proof Agent

- Chrome-free Passivator

- Alloy

- Zinc Dross Remover

- Zinc Pump

Plant Design

It is decided by the land size and white fume-treating methods.

|

1

|

I Type

|

in one straight line

|

white fume: side solution |

High efficiency |

|

2

|

L Type

|

in a shape like an "L"

|

white fume: fixed hood |

Eco-friendly |

| 3 |

O Type |

the rail in a closed loop |

white fume: fixed hood |

High efficiency& Eco-friendly |

Operating temperature

Normal temperature galvanizing refers to the temperature controlled between 435℃ and 460℃, which is suitable for most of the products that need hot dip galvanizing. The minimum temperature of hot dip galvanizing does not have a clear limit, which is subject to the smooth reflux of zinc solution on the surface of steel parts after lifting out of the zinc kettle. With the addition of different alloys, the galvanizing temperature can be reduced appropriately.

At around 500°C, the iron loss increases sharply, almost in a linear relationship. Below 480°C or higher than 510°C, the iron loss increases slowly with time. Therefore, people call 480°C-510°C the malignant dissolution zone. In this temperature range, molten zinc has the most serious corrosion to steel parts and zinc kettles, and the iron loss increases significantly above 560℃. When the temperature is above 660℃, molten zinc will destructively corrode the iron matrix, and zinc dross will increase sharply, making galvanizing impossible to get on. Therefore, currently galvanizing is mostly in the two ranges of 435℃-460℃ and 520℃-560℃.

Advantages

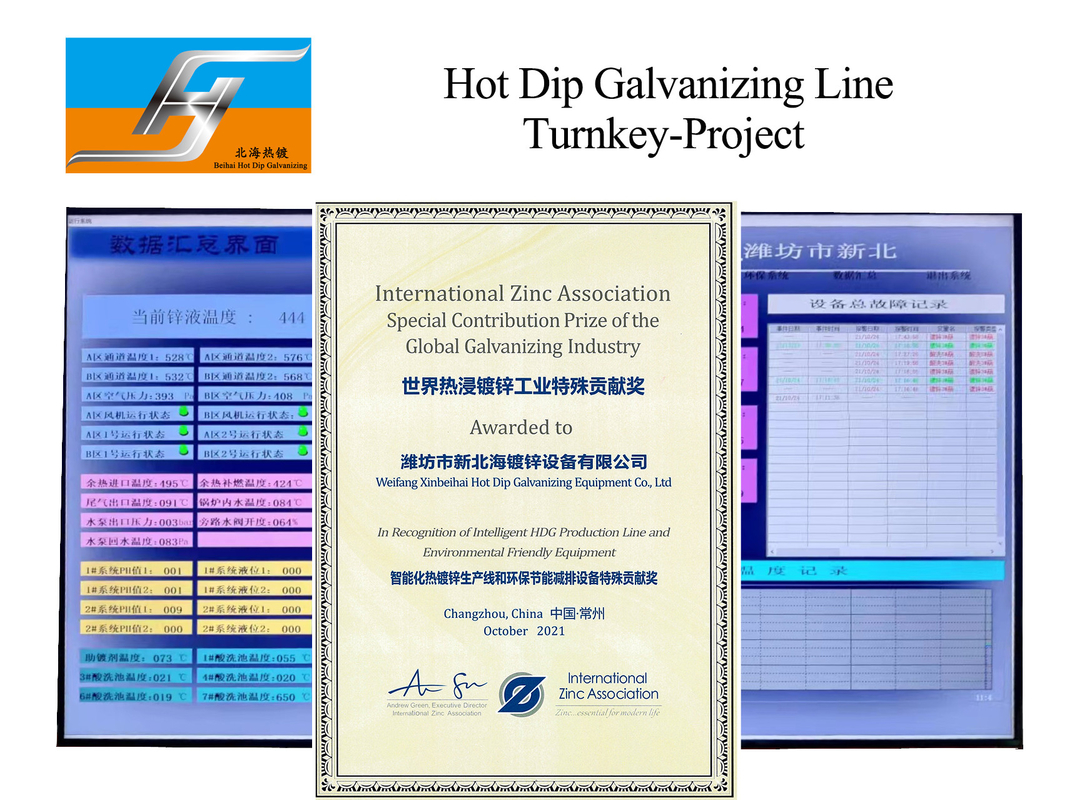

Professional designer and manufacturer of galvanizing lines.

1. Who we are:

we are a planner and manufacturer of complete galvanizing plants for the hot-dip galvanizing industry.

We offer plant layout planning, supply the galvanizing equipment, install and start up the hot-dip galvanizing plant, train the personnel and provide technical consulting.

2. Have confidence in us:

With more than 27 years of experience in the hot-dip galvanizing industry, our product range will meet your requirements. And our equipment is tested by our worldwide customers, they are all satisfied with the high quality and acceptable price.

3. To know us better:

If you want to know whether your money is worth buying our equipment and whether our company has the ability to meet your requirements, we are expecting a facial conversation with you to solve your questions and to let you know what can we do.

Contact Us

If our products interest you, please contact us.

Meanwhile, please tell us the following information.

-

Materials to be galvanized

-

Biggest dimension or kettle size

-

Maximum weight

-

Maximum capacity per year

-

Power source

-

Fuel

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!